The heated clean air enters into the drier and will make all kinds of liquid of raw material atomize and become small drops through nozzle with two fluids(or three fluids).The drop of raw matrial will carry out heat exchange with hot air and the moisture(or solvent)in the liquid raw material will be evaporated out and exhausted along with hot air.The finished product of powder of granule will be got.

It is suitable for drying ordinary solution at high or low temperature.Particularly thin best drying effect can be got for raw materials that have viscosity,paste,or thin slurry.Other equipment cannot replace it in deed.

The atomizing equipment has reasonable structure and is very convenient to maintain and has low cost in operation and is suitable for auto flow production process.

The finished product may be powder or granule.Customer can adjust the size of finished product in accordance with practical need.

The finished product of powder has good liquidity and the finished product of granule has high real density and appears ball basically.

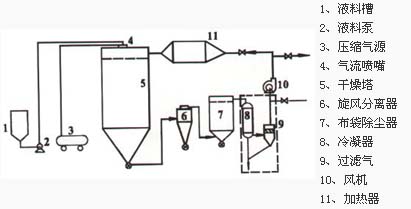

1、Tank of liquid material

2、Pump of liquid material

3、Compressed air

4、Nozzle of air stream

5、Drying tower

6、Cyclone

7、Cloth bag duster

8、Condenser

9、Filter

10、Fan

11、Heater

Foodstuff:

flavoring 、essence、coffer、soy、starch、protein,etc.

Pharmaceutical:

Vitamin、amino acid、biology product、preparation of Chinese traditional medicine,etc.

Chemical industry:

ore products、graphite、 kaoline、etc.

|

Parameter\Type |

5 |

25 |

50 |

100 |

150 |

200 |

|

Evapporated amount

kg/h |

△t=150℃-90℃ |

1.5 |

7.5 |

15 |

30 |

45 |

60 |

|

△t=200℃-100℃ |

2.5 |

12.5 |

25 |

50 |

75 |

100 |

|

△t=250℃-100℃ |

3.75 |

18.75 |

37.5 |

75 |

112.5 |

150 |

|

△t=300℃-100℃ |

5 |

25 |

50 |

100 |

150 |

200 |

|

△t=350℃-110℃ |

6 |

30 |

60 |

120 |

200 |

240 |

|

Compressed air (m3/min) |

0.3 |

0.4 |

0.6 |

1.5 |

2.7 |

3.4 |

|

Compressed air(Mpa) |

0.4 |

0.6 |

0.7 |

|

Way of heat source |

Electricity,electricity plus steam,coal(oil)fuel hot air furnace |

|

Heat amount to be supplied

104kcal/h |

1 |

5 |

10 |

20 |

30 |

40 |

|

power of fan

kw |

0.75 |

2.2 |

4 |

7.5 |

11 |

15 |

| Notes:1.If equipment is over than Model 200,it can be designed and manufactured in accordance with the practical needs;2.The power of fan is suitable for standard flow chart。If need cloth bag duster and solvent recover,the power of fan should be increased. | |