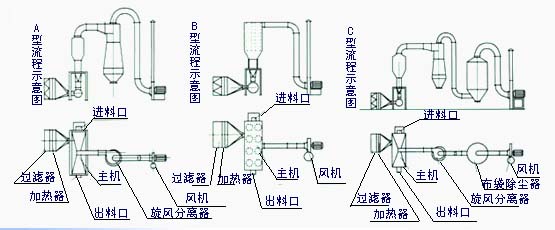

Boiling dryer, also known as fluidized bed, after 30 years of use, improvement, in the pharmaceutical, chemical, food, Food processing, it reflects the increasingly important role. It is by air filters, boiling bed mainframe, Cyclone, bag filter, high pressure centrifugal fan, the control desk component. Due to the nature of the materials dry, dust ancillary equipment, according to need and can also choose Cyclone, bag filter, or to choose one of them. In general, a large proportion of the materials only in selecting Cyclone. The lighter weight materials required matching bag filter, and with pneumatic feeding devices available.

Boiling dryer is the use of filtering after the clean air, heat exchangers by the convection heat transfer, Air temperature will rise to a temperature of the wind into the mainframe-SR, valve plates for distribution to boiling. Wen materials from the feed entered the dryer, as the wind pressure, material formed in dryer boiling point, Hot air and materials for extensive contacts, and enhanced heat and mass transfer process. in a relatively short time to get the materials separation of water evaporation, the equipment has been conducted generally negative pressure operation. 0.1-6mm, the best size of 0.5-3mm.

Pharmaceutical drugs, chemicals, food, food processing, feed drying operations. Such as : raw material compression particles, Chinese medicine granules, food and beverages granules, corn germ, and feed, plastic resins, and other citric acid powder, granular materials drying dehumidifier. Drive general stores for 0.1-6mm, the best size of 0.5-3mm.

Display equipment required the formation, by the end of the screw fixation feet of the various components good seal.

Fan can display on the indoor or indoor self silencers. Layout under specific circumstances, as appropriate adjustment.

|

Technology projects |

Drying capacity |

Fan power |

Pressure |

VAV |

Progressive Wind temperature |

Largest expendable |

Dimensions |

Filling forms |

|

A |

B |

C |

|

XF10 |

10-15 |

7.5 |

5.5×103 |

1500 |

60-200 |

2.0×108 |

4*3.5*3.2 |

3.5*3.5*3 |

5*3.5*3.5 |

1、Filling the star

2, pneumatic conveying their own |

|

XF20 |

20-25 |

7.5 |

5.8×103 |

2000 |

60-200 |

2.6×108 |

4.5*4*4.2 |

4*4*3.2 |

6*4*4.5 |

|

XF30 |

30-40 |

15 |

7.1×103 |

3850 |

60-200 |

5.2×108 |

5*4*4.5 |

4*4*4.2 |

6*4*5 |

|

XF50 |

50-80 |

30 |

8.5×103 |

7000 |

60-200 |

1.04×108 |

5*4.8*4.8 |

4*4.8*4.5 |

6*4.8*5 | Note : drying capacity and materials and solid content and temperature of the hot air import and export. Here is the drying capacity of grain drying dark plum early moisture 20%, 5% moisture end, inlet temperature of 130 ° C, Selection of the need for attention.

|