1.Screw extrusion mechanism particles, rock particles, wet granulation mixed high-speed particles.

2.Medicine, food, feed, chemicals and other fields wet mark and dry powder materials.

3.Large particles, small block, viscous block granular materials.

4.Konjac, polyacrylamide, and other dry bulk materials changes.

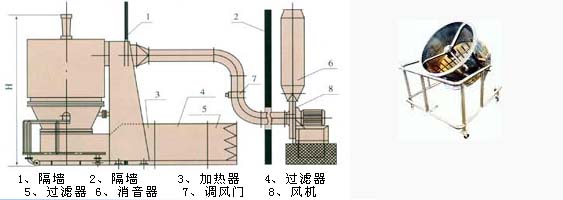

Air purification by heating from the lower Fan from introduction, through the pore network hopper plate. The indoor work, mixing and vacuum formed fluidization, the rapid evaporation of water after the exhaust away with the materials, rapid drying.

1.CFB circular structure to avoid dead ends.

2.Hopper set, stirring to avoid wet and dry materials reunion formed ditch flow.

3.Used over dumping tablets, and facilitate rapid and complete may also request automatic access to design information systems.

4.Confined vacuum operation, flow through filter. Simple, clean washing convenience, is "GMP" the ideal equipment requirements.

5.Drying speed, temperature uniformity, each consisting of a general drying time in 20 -30 minutes.

|

Project |

Systems |

|

Feeding |

Kg |

60 |

100 |

120 |

150 |

200 |

300 |

500 |

|

Fans |

VAV |

m3/h |

2361 |

3488 |

3488 |

4901 |

6032 |

7800 |

10800 |

|

Pressure |

mmH2O |

594 |

533 |

533 |

679 |

787 |

950 |

950 |

|

Power |

Kw |

7.5 |

11 |

11 |

15 |

22 |

30 |

45 |

|

Mixing power |

Kw |

0.55 |

0.55 |

0.55 |

0.55 |

0.75 |

0.75 |

1.1 |

|

Mixing speed |

rpm |

11 |

|

Steam consumption |

Kg/h |

141 |

170 |

170 |

240 |

282 |

366 |

451 |

|

Operating hours |

min |

15~30 |

|

Host height H |

Square |

mm |

2750 |

2850 |

2850 |

2900 |

3100 |

3300 |

3650 |

|

Circular |

mm |

2700 |

2900 |

2900 |

2900 |

3100 |

3600 |

3850 | |