rature axial fan and automatic temperature control system, the entire circulatory system-wide closed. oven so that the thermal efficiency of the drying room from the traditional 3 -7% of the current 35-45% The maximum thermal efficiency of up to 50%. CT-C-type hot air circulating oven design success, so that the hot air circulating my oven at home and abroad reached the advanced level. To save our country a lot of energy, and to improve the economic efficiency of enterprises. In 1990, the State Pharmaceutical Administration issued the standards of conduct, unified model of RXH.

Applicable to the pharmaceutical, chemical, food, agricultural products, aquatic products, light industry, heavy industry and other sectors of materials and products in heating curing, dehydration. Raw materials such as medicine and Chinese herbs, Chinese Herbal Medicine, extracts, powder, granules, granules, water-, packaging bottles, paint dyes, dehydrated vegetables, dry fruits, sausages, Plastic resin, electrical components, such as baking finish 。

Most of the hot air inside circle, high thermal efficiency, energy conservation. The use of forced ventilation, boxes with adjustable wind-plate materials uniform drying, use steam heat, hot water, electricity, Far-infrared, a wide choice. Small piece of noise, the running balance. Temperature-controlled, installation and maintenance convenience. Wide application and can be drying of various materials, the common drying equipment.

|

- A heating steam heat, electricity and steam -- Far-infrared dual-use for users to choose.

- Temperature : steam heating 50 -140 °C, maximum 150 ° C

- Electricity, far infrared temperature50-350℃。

- With a computer-controlled system and control system for users to choose.

- Common steam pressure 0.02-0.8mpa(0.2-8kg/cm2)

- Heating distribution of electricity by a calculation of 15-kw, practical 5-8kw / h

- Special requirements of the specifications indicate.

- Non-standard oven Mixograph prices.

- Temperature greater than 140 ° C or less than 60 ℃, the procurer when annotated.

- The plant manufactured cars scones, scones disk size reunification, interchangeable.

- Bake disk size:460X640X5

|

|

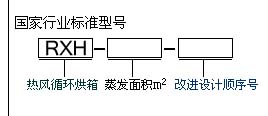

Industry standard models |

Model specifications |

Each volume drying |

Wearing Power |

Steam consumption |

Thermal

Area |

Amount of wind |

The next

Thermoelectric |

Wear

Bake plate |

Dimensions

Broad x Depth x High |

Matching scones car |

|

RXH-14-B |

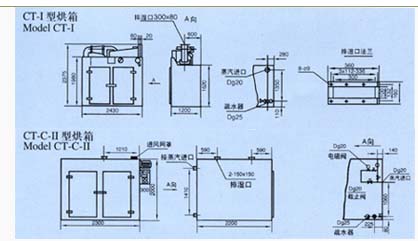

CT-I |

100 |

1.1 |

20 |

20 |

1400 |

±2 |

48 |

2430x1200x2375 |

2 |

|

RXH-27-B |

CT-II |

200 |

1.1 |

40 |

40 |

5200 |

±2 |

96 |

2430x2200x2433 |

4 |

|

RXH-41-B |

CT-III |

300 |

2.2 |

60 |

80 |

9800 |

±2 |

144 |

3430x2200x2620 |

6 |

|

RXH-54-B |

CT-IV |

400 |

2.2 |

80 |

100 |

9800 |

±2 |

192 |

4380x2200x2620 |

8 |

|

RXH-5-C |

CT-C-O |

25 |

0.45 |

5 |

5 |

3450 |

0 |

16 |

1550x1000x2044 |

0 |

|

RXH-14-C |

CT-C-I |

100 |

0.45 |

18 |

20 |

3450 |

±2 |

48 |

2300x1200x2300 |

2 |

|

RXH-27-C |

CT-C-II |

200 |

0.9 |

36 |

40 |

6900 |

±2 |

96 |

2300x2200x2300 |

4 |

|

RXH-41-C |

CT-C-III |

300 |

1.35 |

54 |

80 |

10350 |

±2 |

144 |

2300x3220x2000 |

6 |

|

RXH-54-C |

CT-C-N |

400 |

1.8 |

72 |

100 |

13800 |

±2 |

192 |

4460x2200x2290 |

8 |

|

RXH-18-C |

CT-C-IB |

120 |

0.9 |

20 |

25 |

6900 |

±1 |

48 |

1460x2160x2250 |

2 |

|

RXH-41-B |

CT-C-IS |

Exclusive bottle-drying |

2.2 |

60 |

100 |

6900 |

±2 |

|

1140x6160x3240 |

6 |

|

RXH-25-A |

|

Efficient high-temperature sterilization far-infrared oven |

1200x1000x1600 |

1 | |